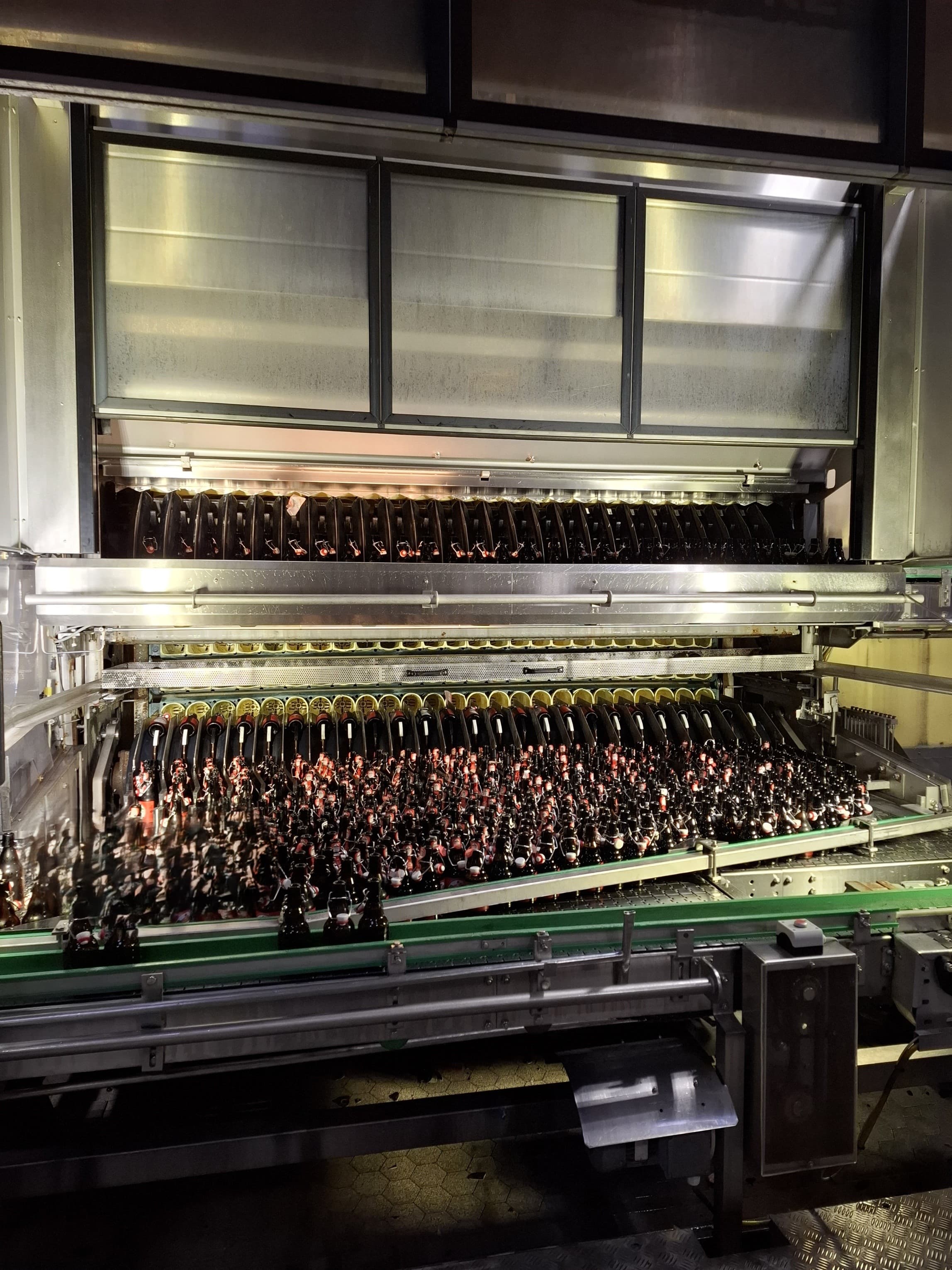

Krones Lavatec KES Bottle Washer (1998)

Country:

Germany

Year:

1998

Category:

Washing

Manufacturer:

Krones

Model:

Lavatec KES

Availability:

Sold

SKU:

DE-WAS-KRO-1998-00001

Overview

The bottle washer was manufactured in 1998 by the German company Krones. It is located at a German mineral fountain and is part of a line that has been shut down because the operator will be bottling in glass in the future and no longer in PET. The bottle washer is still assembled.

Technical data

- Capacity: 44,000 bph

- Control range: 17,000 - 50,000 bph

- Bottles per row: 35

The Machine in Detail / Equipment Features

- Residual emptying

- Pre-soak/ pre-caustic

- High pressure pre-spraying with automatic screen discharge

- Machine multi-part with 3 shocks

- Pre-soak, water zone incl. head section

- Discharge in V2A

- Post-leach immersion bath KES

- Post-leaching area in V2A

- Bottle cell in steel with plastic mouth

- Feeding table in VA

- Insertion finger feed with safety shutdown

- Discharge with pick-up finger and safety cut-out

- Muzzle basket control at the ejector

- Shard ejector behind the delivery with

- Shard collecting tray

- Insulated area

- the side walls in the area of the pre-liquor and main liquor as well as post-liquor

- the roof in the area of the main liquor and the final liquor

- the exchange lines

- Label collecting belt in V2A with plastic belt

- Sieves

- Autom. fine screen discharge post leach, warm water 1 and 2

- Cold water, with intermittent sieve belts and sieve belt rinsing for basic machine and pre-suds

- Additional rinsing pipes in the screen boxes

- KRONES rotary pipe spray

- Degassing: steam exhaust fan in V2A with throttle valve

- Heating

- Designed for a heating water system with a flow temperature of less than 120 degrees C

- Heating medium: heating water 108 degrees C inlet temperature

- Concentration measurement

- Caustic concentration measuring system in the main caustic with display on the touch screen

- Main leach concentration 1.5%

- Caustic concentration measuring system in the pre-caustic tank with display on the touch screen

- Pre-leach concentration min. 1%

- Conductivity controlled post leach

- Central lubrication:

- Make Lincoln

- Lubrication lines made of V2A (partly of plastic)

- Complete temperature control

- Jam - lack - regulation with autom. restart in stop and go mode

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

If you have any further questions please contact us

Carsten Hormes

Your Account Manager

CLICK TO CHAT ON WHATSAPP

Related Products

Krones - 1996 - Germany

Bottle Washer

45,000 €

GM Gera - 1999 - Germany

Bottle Washer

52,000 €

PAC - 1995 - Germany

Bottle Washer

42,000 €

PAC - 1996 - Germany

Bottle Washer

45,000 €

GM Gera - 1993 - Germany

Bottle Washer

39,000 €

Krones - 2013 - Germany

Bottle Washer

450,000 €

HOBART - 2009 - Germany

Crate Washer

12,900 €

Klotzki - 2011 - Germany

Crate Washer

37,000 €

Klinger - 2000 - Germany

Bottle Washer

Price Upon Request

MAG - 1995 - Germany

Bottle Washer

75,000 €

Krones - 2011 - Germany

Bottle Washer

350,000 €

Bohrer - 2000 - Germany

Crate Washer

22,000 €

Ellpress - 2016 - Germany

crate washer

Price Upon Request

GM Gera - 2010 - Austria

Bottle Washer

175,000 €

GM Gera - 2024 - Germany

Bottle Washer

350,000 €

KITZINGER - 2009 - Germany

crate washer

14,000 €

GM Gera - 1994 - Germany

Bottle Washer

59,000 €

NOWICKI/ NOMA - 2022 - Germany

crate washer

19,800 €