ALWID ATEX Filling Line (2021)

1,050,000 € (ExWorks)

Get an official quote

Fill in the information below to receive an official quote on the machine you have selected.

Country:

Germany

Year:

2021

Category:

Complete Filling Lines

Manufacturer:

ALWID

Model:

ATEX

Availability:

Immediately

SKU:

DE-COM-ALW-2021-00001

Overview

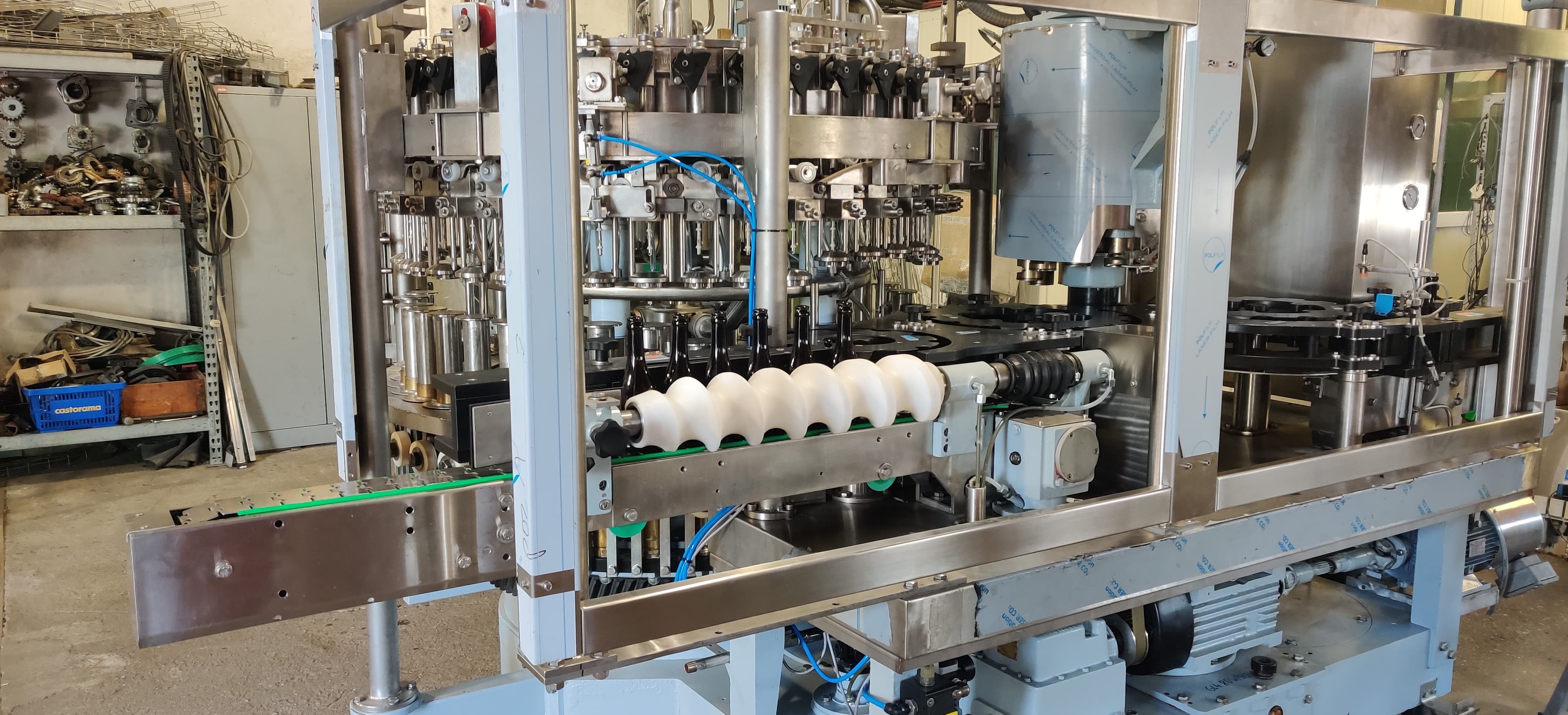

The filling line was manufactured in 2021 by the German company ALWID. The filling line is new and can fill chemical products into plastic containers. With the exception of the bottle feeder and Posimat, glass bottles can also be processed. Due to ATEX certification, explosive products can be processed with the line. The equipment comes with a 2-year warranty (in single-shift operation) and all components of the equipment can be purchased separately.

Technical details

- Capacity: 9000 containers/h (varies according to bottle volume and product).

- Container

- Max. Diameter: 100mm

- Max. Height: 300mm

- Control Siemens S7

Single machines

Bottle Hopper | ALWID | POSIMAT-ACCESS-N15

- Bottle feeder with hopper 2000 l, in stainless steel, chassis and supports in mild steel painted

- Positronic control system for optimal adaptation to downstream filler

- Machine, completely internally wired with attached control cabinet in mild steel, painted

- Machine according to CE guidelines; i.e. max. noise level of ≤ 80 dB +/- 2

Combined filling and closing machine (block machine) | ALWID | SUPERIOR-16MDM-5SK

- Fully automatic rotary filler

- Filling system: mass flowmeter system, type: Endress+Hauser LPG MASS

- Number of filling stations: 16 filling stations

- Filling valve diameter: Ø12mm

- Max. tank dimensions: height: 50-300 mm, Ø: 20-100 mm

- Fully automatic round capper

- Number of capping heads: 5

- With torque adjustment via slip clutches

- With fully automatic cap sorting and cap feeding via BONINO disc sorter with elevator

- With inside drop switch to switch off the machine in case of missing closures

Checkweigher | ALWID | OCS-HC-M-2000-1

- Applied safety and machinery directives CE compliant

- Industrial load cell with stainless steel housing based on the principle of electromagnetic force compensation

- Force shunt free current transfer at the load cell

- Front protection to reduce interference on the weighing result

- Stainless steel control cabinet

- Graphics-capable color TFT touch screen, 10.4 inch, VGA resolution

- Flexible operability due to tiltable stainless steel operator terminal

- Freely configurable user interface with simple, intuitive operation

Inkjet Printer | Domino | Ax350i

- Fast printing of text and multi-line codes at high speeds

Labeler | ALWID | SES-120-III

- Tandem design

- Max. Label height: 120mm

- Photocell for label scanning

- 2 x automatic winding station incl. counter pressure plate

- Mounting device with height adjustment for lateral label dispensers

- With adjustable side guides - passage width up to 150mm

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

If you have any further questions please contact us

Carsten Hormes

Your Account Manager

CLICK TO CHAT ON WHATSAPP

Related Products

Krones - 2002 - Italy

Line for Non-Returnable PET Bottles

Price Upon Request

Krones - 2005 - Denmark

Line for Non-Returnable PET Bottles

Price Upon Request

Krones - 2012 - Germany

Line for Returnable Glass Bottles

750,000 €

Cimec - 2016 - Spain

Non-Returnable Glass Bottles

65,000 €

Nissei ASB - 2003 - Spain

Kosme - GyM- SMI

Price Upon Request

Kohem (now CIMEC) - 2014 - Sweden

Kosme - GyM- SMI

40,000 €

SIDEL - 2012 - Spain

Line for Non-Returnable PET Bottles

Price Upon Request

SERAC - 2007 - Spain

Line for Non-Returnable PET Bottles

420,000 €

Linapack, Kreuzmayr - 2018 - Germany

Line for Pouch Bags

250,000 €

Wild Goose - 2021 - Finland

Line for Returnable Glass Bottles

59,000 €

Wild Goose - 2022 - Germany

Line for Cans

85,000 €

PROCOMAC / PE / - 2001 - Greece

Line for Returnable Glass Bottles

Price Upon Request

KHS - 2015 - Germany

Line for Cans

Price Upon Request

H & K - 2016 - Germany

Line for Returnable Glass Bottles

66,000 €

SIG Corpoplast, KHS - 2000 - Germany

Line for Non-Returnable PET Bottles

1,150,000 €

Project AE - 2020 - Germany

Non-Returnable Glass Bottles

90,000 €

GYM Internacional - 2011 - Spain

Line for Non-Returnable PET Bottles

45,000 €

Hamba - 1997 - Germany

Filling Line

125,000 €

SIPA, Procomac - 2000 - Germany

Line for Non-Returnable PET Bottles

195,000 €

RICO, ADELSKI, PAC - 2011 - Germany

Line for Returnable Glass Bottles

295,000 €

Comac - 2018 - United Kingdom

Line for Cans

250,000 €

Nagema - 2022 - Spain

Line for Non-Returnable Glass Bottles

399,500 €

Hamba - 2002 - Germany

Filling Line

187,500 €

Steelhead - 2003 - Germany

Filling Line

40,000 €

EUROSTAR - 2014 - Mexico

Line for Non-Returnable Glass Bottles

70,000 €