Hormes KHS, Krones, 15,000 bph Line for Non-Returnable Glass Bottles (2015)

Country:

Sweden

Year:

2015

Category:

Complete Filling Lines

Manufacturer:

Hormes

Model:

KHS, Krones, 15,000 bph

Availability:

Sold

SKU:

SE-COM-HOR-2015-00001

Overview

This filling line was part of a whole brewery and was assembled in 2015 by German manufacturer Hormes. The line will be dismantled soon. The bottling line recently ran at 15,000 bph with 0.33L glass bottles.

Components

- Glass Depalletizer | Hormes

- Set up for 1 pallet size, new glass pallet: 1000 mm x 1200 mm

- The chain hoist is driven by an electric motor.

- The traverse has a length of approx. 4,500 mm

- Fully automatic rinser | Hormes

- Capacity: up to 15,000 bph

- Number of spray nozzles at least 36

- Equipped for 1 bottle type

- The inside of the bottles is sprayed with fresh water

- Spraying with fresh water approx. 1.5 sec., draining approx. 5 sec.

- Inlet auger, star wheels and guides are easily replaceable

- Machine cladding made entirely of stainless steel

- Electrical connected load: 230/400V, 50Hz, approx. 4 kW.

- With new S7 control system

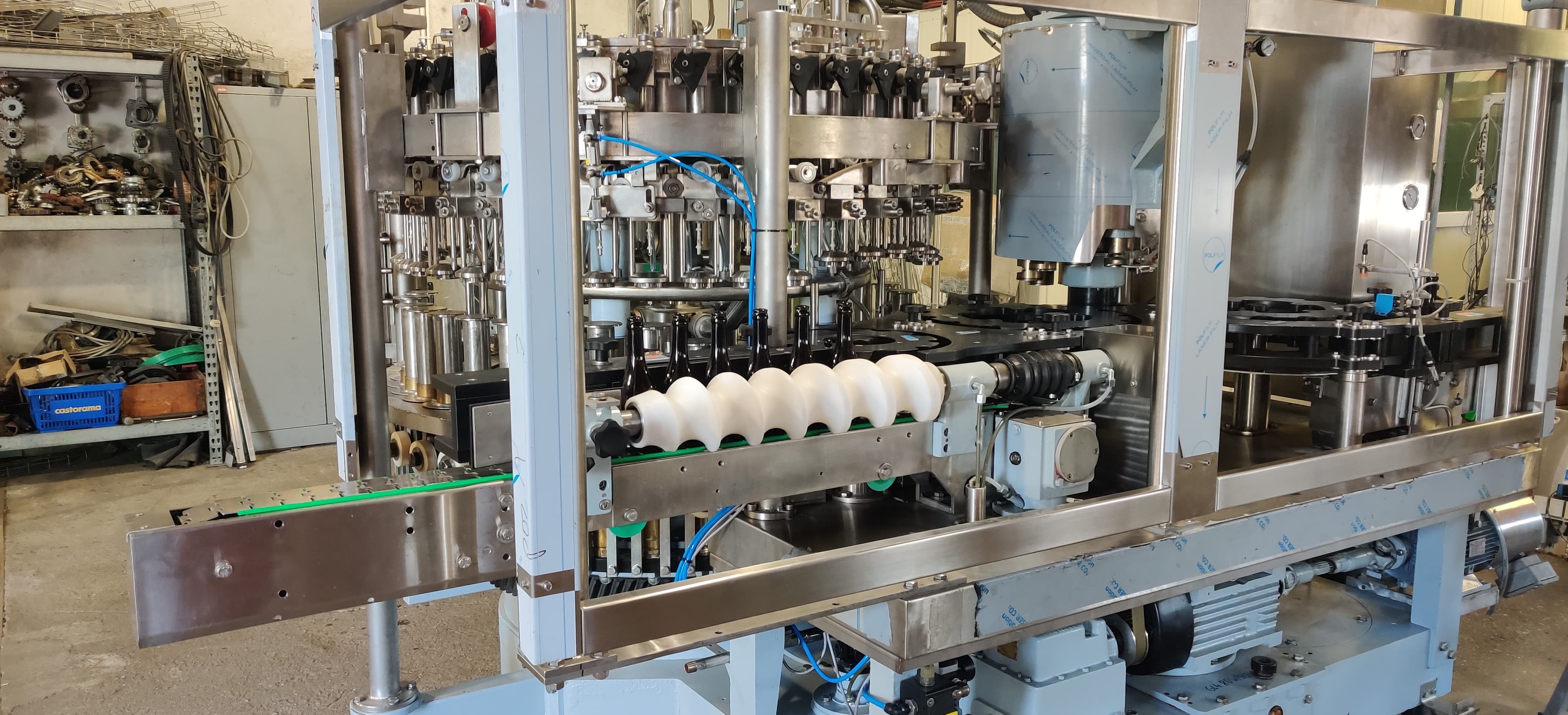

- Automatic bottle filling and capping machine | KHS

- Number of filling valves: 50

- Number of capping points: 10 for standard crown corks, 26 mm

- Filling capacity: up to 15,000 bottles/h

- All parts in contact with the product are made of stainless steel

- Electrical connection: 230/400V, 50Hz, control voltage 24V DC

- Pneumatic cap loading system | Hormes

- Fully automatic labeling machine | Krones

- Output: up to 16,000 bottles/h

- Prepared for processing the following equipment:

- Belly, back and breast label, i.e. with 2 units, label length max. 130 mm

- Modern design standing on height-adjustable feet

- With automatic bottle stop

- S7 control, 2 pneumatic glue pumps

- Carton packaging machine | Wrapapack

- For packaging bottles in full cartons or trays

- With magazine compartment for inserting the carton blanks.

- With hot melt unit

- Frequency-controlled main drive

- Electrical equipment S7 control

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

If you have any further questions please contact us

Carsten Hormes

Your Account Manager

CLICK TO CHAT ON WHATSAPP

Related Products

Krones - 2002 - Italy

Line for Non-Returnable PET Bottles

Price Upon Request

Krones - 2005 - Denmark

Line for Non-Returnable PET Bottles

Price Upon Request

Krones - 2012 - Germany

Line for Returnable Glass Bottles

750,000 €

Cimec - 2016 - Spain

Non-Returnable Glass Bottles

65,000 €

Nissei ASB - 2003 - Spain

Kosme - GyM- SMI

Price Upon Request

Kohem (now CIMEC) - 2014 - Sweden

Kosme - GyM- SMI

40,000 €

SIDEL - 2012 - Spain

Line for Non-Returnable PET Bottles

Price Upon Request

SERAC - 2007 - Spain

Line for Non-Returnable PET Bottles

420,000 €

Linapack, Kreuzmayr - 2018 - Germany

Line for Pouch Bags

250,000 €

Wild Goose - 2021 - Finland

Line for Returnable Glass Bottles

59,000 €

Wild Goose - 2022 - Germany

Line for Cans

85,000 €

PROCOMAC / PE / - 2001 - Greece

Line for Returnable Glass Bottles

Price Upon Request

KHS - 2015 - Germany

Line for Cans

Price Upon Request

H & K - 2016 - Germany

Line for Returnable Glass Bottles

66,000 €

SIG Corpoplast, KHS - 2000 - Germany

Line for Non-Returnable PET Bottles

1,150,000 €

Project AE - 2020 - Germany

Non-Returnable Glass Bottles

90,000 €

GYM Internacional - 2011 - Spain

Line for Non-Returnable PET Bottles

45,000 €

Hamba - 1997 - Germany

Filling Line

125,000 €

SIPA, Procomac - 2000 - Germany

Line for Non-Returnable PET Bottles

195,000 €

RICO, ADELSKI, PAC - 2011 - Germany

Line for Returnable Glass Bottles

295,000 €

Comac - 2018 - United Kingdom

Line for Cans

250,000 €

Nagema - 2022 - Spain

Line for Non-Returnable Glass Bottles

399,500 €

Hamba - 2002 - Germany

Filling Line

187,500 €

Steelhead - 2003 - Germany

Filling Line

40,000 €

EUROSTAR - 2014 - Mexico

Line for Non-Returnable Glass Bottles

70,000 €