Shangdong 20 hl Brewhouse (2020)

Country:

Belgium

Year:

2020

Category:

Brewing & Fermenting

Manufacturer:

Shangdong

Model:

20 hl

Availability:

Sold

SKU:

BE-OTH-SHA-2020-00001

Overview

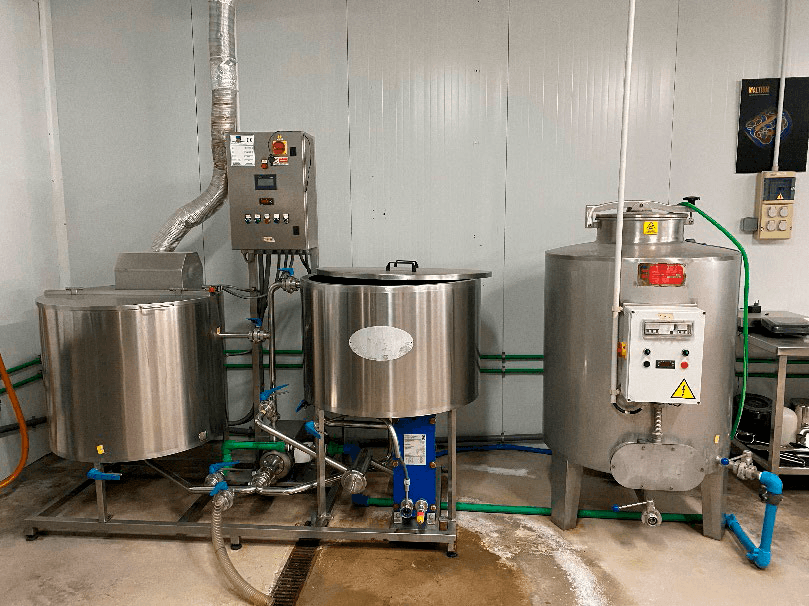

The micro brewery was manufactured in 2020 by the manufacturer Shangdong. All equipment is in good condition, as it is still young. Besides the brew block and the cold fermentation block, there is a filling line for glass bottles.

List of equipment:

1. 20hl manual brew block with platform (5 tanks):

- Production capacity: 2 brews of 20hl in 9 hours with 1 person

- Bigbag station with load cells and conveyor screw to crusher

- Crusher 1.5T/H + conveyor screw to mixing tank

- Brew kettle

- Lauter tank (electric desiccation with variator)

- Boil kettle (25hl, with external grille)

- Whirlpool tank

- 30HL hot water tank

- 40HL water reserve tank

- Plate heat exchanger 338KW (35hl/H)

- Steam piping: DN50 for the main supply, DN25 for supplying the tanks (line, trap, vacuum breakers, regulation valves etc. line steam capacity 600kg/H)

- 3x stainless steel analog flowmeters (brewing water, rinsing water, filtration tank outlet)

- 1x Stainless steel magnetic flowmeter at plate heat exchanger outlet

- 2x 4m tri clamp food hoses DN38 (high pressure rated)

- 3x 8m food hose 38mm (low pressure rated )

- 4 stainless steel centrifugal pumps

- CIP 2x200L (cleaning in place 2 tanks (including 1 heated by 2 electrical resistances) + pump)

- Thermindus 300kg/H steam generator, propane

2. Cold block (installed fermentation capacity 220hl):

- 5 x isobaric 20hl tanks (3bar), double jacketed, insulated, manhole on top with PID regulator and solenoid valve

- 3 x isobaric 40hl tanks (3bar), double jacketed, insulated, manhole on top With PID regulator and solenoid valve - Stainless steel glycol circuit in DN50

- Hopgun 200L - Pneumatic pump (3m²/h)

- Injection tank isobaric 100L - fizzwizz v2 (saturation by automated CO2 injection in tank)

- Isobaric linear filler (1500 bottles/h in isobaric, 2000 bottles/h in atmospheric)

- Labeling machine (ENOS compatta, body labeling station + collar station, 3000 bottles/h)

- Rotary capper (6 heads, 6000 bottles/h)

- Taping machine + conveyor for case exit

- Rectangular exit accumulation table 160x120cm

- Round infeed accumulation table 100cm

- Conveyor belts linking the whole (U-shaped)

- Cooling unit, TAE evo TECH 121/P3, refrigerating capacity 35KW

3. Utilities:

- Screw compressor ‘contimac’ NS10/270, tank 270L

- Pneumatic air dryer ‘Nuair’

- Negative cold room 6,1m³

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

If you have any further questions please contact us

Carsten Hormes

Your Account Manager

CLICK TO CHAT ON WHATSAPP

Related Products

ProminoxVillarobledo - 2016 - Spain

Brewhouse

250,000 €

ZIP Technologies - 2014 - United Kingdom

Brewhouse

190,000 €

Beraplan - 1999 - France

Brewhouse

180,000 €

Speidel - 2020 - Finland

Fermentation and storage cellar

15,000 €

Braucraft - 2016 - Mexico

Brewhouse

100,000 €

SK Group & Céspedes - 2014 - Spain

Fermentation and storage cellar

35,000 €

Slowbeer - 2015 - Spain

Brewhouse

26,000 €

Sirio Aliberti - 2007 - Italy

Fermentation and storage cellar

60,000 €

Spadoni - 2022 - Spain

Brewhouse

389,000 €

Slowbeer, Toscana - 2013 - Spain

Brewhouse

30,000 €

Finnish 1.000 L - 2017 - Finland

Brewhouse

11,500 €

Spadoni - 2022 - Spain

Brewhouse

1,000,000 €

INOXDUBRA - 2020 - Spain

Lauter Tun

25,000 €

Certuss,SKRLJ DOO - 2018 - Romania

Brewhouse

160,000 €

INOXDUBRA - 2017 - Spain

Brewhouse

150,000 €

Flecks - 2013 - Lithuania

Brewhouse

225,000 €

ETD - 2014 - Spain

Brewhouse

59,000 €

Kaspar Schulz - 2010 - Sweden

Brewhouse

315,000 €

Cespedes - 2015 - Spain

Brewhouse

85,000 €

Mini Brewry System - 2012 - Spain

Brewhouse

50,000 €

Slowbeer - 2019 - Spain

Brewhouse

30,000 €

Spadoni - 2019 - Spain

Fermentation and storage cellar

9,750 €

Hansteel - 2017 - Czech Republic

Brewhouse

52,500 €

Labu - 2017 - Switzerland

Brewhouse

85,000 €

Spadoni, Videojet - 2014 - Spain

Brewhouse

61,650 €